¶

M1pro Model TPU 85A and 90A Printing Guide

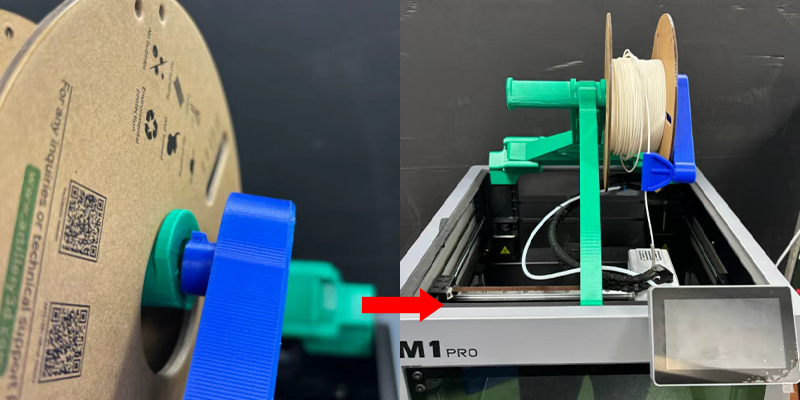

When using TPU 85A and 90A materials on the M1PRO. Please feed directly from above the tool head.

TPU 85A and TPU 90A are two different hardness grades of thermoplastic polyurethane (TPU) material.

Hardness: The hardness of TPU is usually expressed in Shore A hardness. 85A and 90A respectively represent the hardness grades of these two materials, with 90A being harder than 85A.

Elasticity and Flexibility: Capable of stretching and bending over a wide range without breaking, with strong recovery. This property makes TPU 85A and TP U 90A perform well in applications requiring elasticity and flexibility.

Abrasion Resistance: TPU material has good abrasion resistance and can main tain stable performance during long-term use.

In terms of applications, TPU 85A and TPU 90A can be used to manufacture products that require elasticity and abrasion resistance, such as shoe soles an d sports equipment parts, and are also suitable for making electronic product accessories such as mobile phone cases and smart watch straps. Overall, the se two thermoplastic polyurethane materials have excellent performance and are widely used. Different hardness grades enable them to meet the needs of various application scenarios.

TPU filament is prone to moisture absorption, and moisture will affect the pri nting quality. To avoid this, it is recommended to store the filament in an en vironment with a humidity below 20% RH. Use a storage box for storage and place a desiccant in the box, preferably a desiccant, to keep the filament dry.

Place desiccant in the storage box:

|

TPU material has strong hygroscopicity and easily absorbs moisture in the nat ural environment. If TPU containing moisture is directly used for 3D printing, the moisture will rapidly vaporize when heated during the printing process, fo rming bubbles, voids and other defects in the printed product, which seriousl y affects the printing quality and may even lead to printing failure. Therefore, we recommend that you use the following equipment and parameters for dr ying. See details: Consumables Preparation - Drying.

| Forced air oven |

| 70 ℃, 8 h |

For the printing effect and quality of TPU material, it is strongly recommende d that you choose a brand new hot end, or a hot end dedicated to printing TPU. The hot end compatibility is as follows:

| Material Line Type | 0.2 nozzle ordinary hot end | 0.4 nozzle ordinary hot end | 0.6 nozzle ordinary hot end | 0.8 nozzle ordinary hot end | Any size high flow hot end |

| TPU 85A | Not applicable | Not applicable | Recommended | Recommended | Not applicable |

| TPU 90A | Not applicable | Recommended | Recommended | Recommended | Not applicable |

Please note that you should not use a hot end that has been used to prin t fiber-reinforced filaments (such as carbon fiber-reinforced or glass fiber-reinf orced filaments) to print TPU.

Applying glue to a PEI textured printing plate may cause the TPU filament to adhere too much, so it is not recommended to apply glue when using a tex tured plate for printing.

Other types of printing plates need to be coated with glue to prevent poor f irst layer quality, poor adhesion, or even printing failure.

| Materia Low-tempera Engineering Smooth PEI Texture Whether to apply |

| l Line Type | ture printing plate | material printing plate | printing plate/high-te mperature printing plate | d PEI printin g plate | glue |

| TPU 85A | Recommended | Recommended | Recommended | Recomme nded | Yes (except for PEI texture board) |

| TPU 90A | Recommended | Recommended | Recommended | Recomme nded | Yes (except for PEI texture board) |

Check and maintain the extruder (if there are foreign objects, such as materia l residue, please disassemble and wipe it clean). If the feeding gear is worn, i t needs to be replaced (otherwise, the material line may slip).

Pay attention to the wear condition of the cutter blade. After the cutter is w orn, it will affect the TPU top material logic and increase the printing failure rate. It is recommended to regularly check the wear condition of the cutter b lade and replace it according to the tutorial.

If it is not a brand new hot end, please check the hot end status;

Installation of the top material rack and preparation before feeding:

Open the top cover

-2.jpg) |

Remove the original PTFE tube,

-3.jpg) |

Install the top feed rack

-4.jpg) |

-5.jpg) |

-6.jpg) |

Cut and install a new PTFE tube.

|

|

Special Note: When clicking the Extrude button (“Down Arrow”), do not click continuously to avoid TPU getting caught in the extruder gears and causing a blockage. After the extruder gears engage the TPU filament, slowly click the Extrude button to confirm that the filament is extruding continuously and evenly from the hot end before starting printing.

-12.jpg) |

TPU 85A filament cannot be fed through the PTFE tube (this may cause exce ssive loading resistance, and the filament may not be extruded smoothly)

In addition to the preset parameters, the specific parameter settings should b e adjusted according to the characteristics of the model.

The recommended printing temperature for TPU 85A & 90A is 225 ℃, the ho t bed temperature is 30 - 35 ℃, and there is no need to turn on the chamb er temperature.

Please keep the default volume speed limit when printing, it is not recomme nded to increase the printing speed.

TPU material is prone to the following problems:

Material shortage (clogged nozzle, feeding resistance, filament slippage): For more suggestions on M1PRO TPU clogging, please click here to jump

Extruder entanglement (filament is bent and stuck in the extrusion gear, you need to disassemble the extruder and pull out the stuck filament) M1PRO Ext ruder Disassembly and Assembly Guide

Stringing and oozing: You can use a large-diameter hot end (such as a 0.6 m m hot end); fine-tune the retraction parameters; further dry the filament; mod el post-processing

Printing Tips:

- Model Placement: It is recommended to print one item at a time to avoid printing multiple models layer by layer and reduce stringing.

- Part Removal: TPU has strong adhesion, so you can moisten it with alcohol and slowly remove it when taking the part.