¶ Tutorial Guide

|

|

|

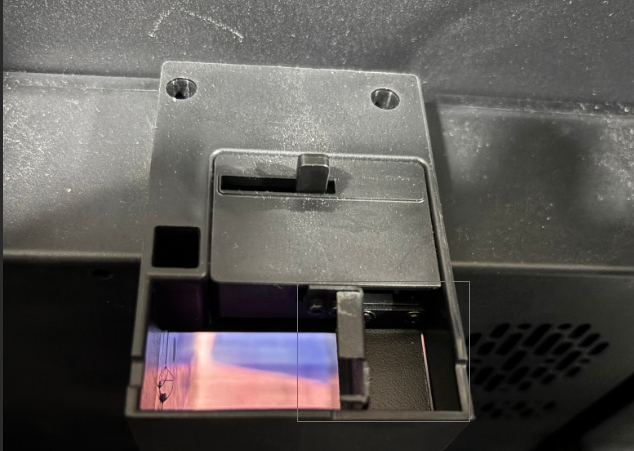

Effect before optimization |

Effect after optimization |

¶ Required tools and materials

Tools:

1. PH0*3.0 Phillips screwdriver

2. H1.5 Allen screwdriver

Materials:

1. Magazine Material Tray

2. Pusher Plate

|

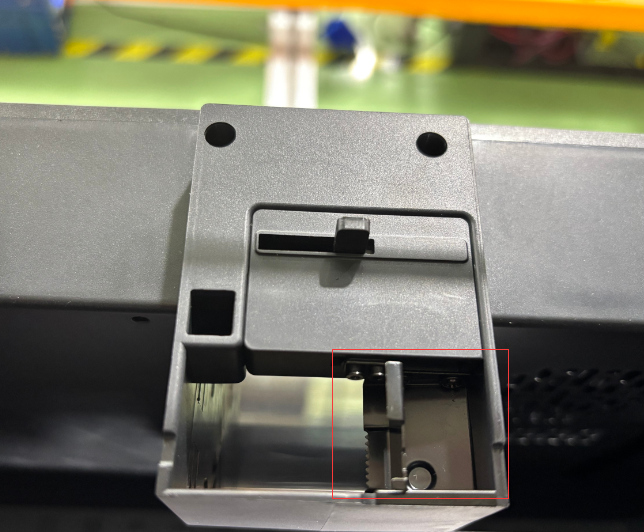

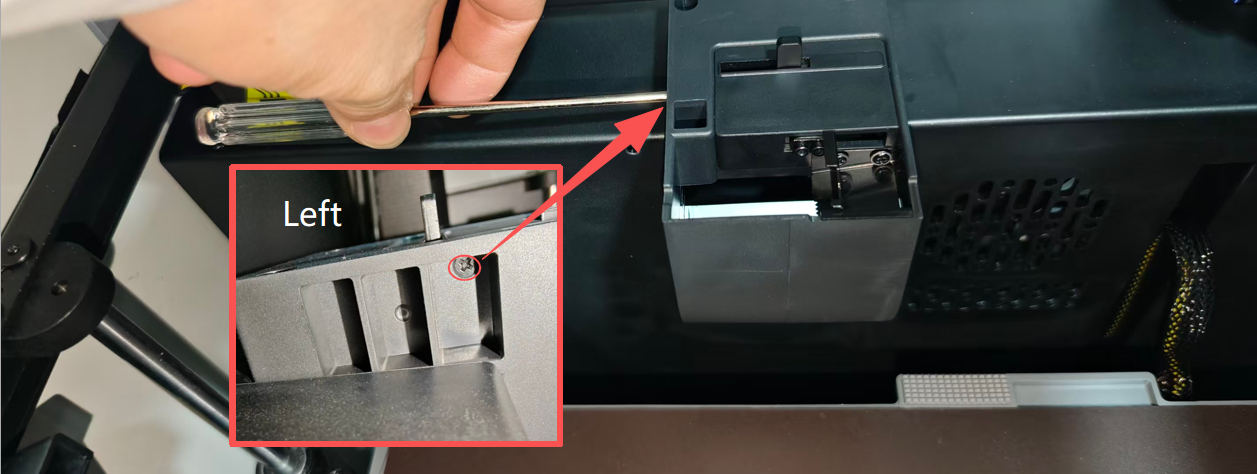

¶ Disassembling the Magazine Material Assembly

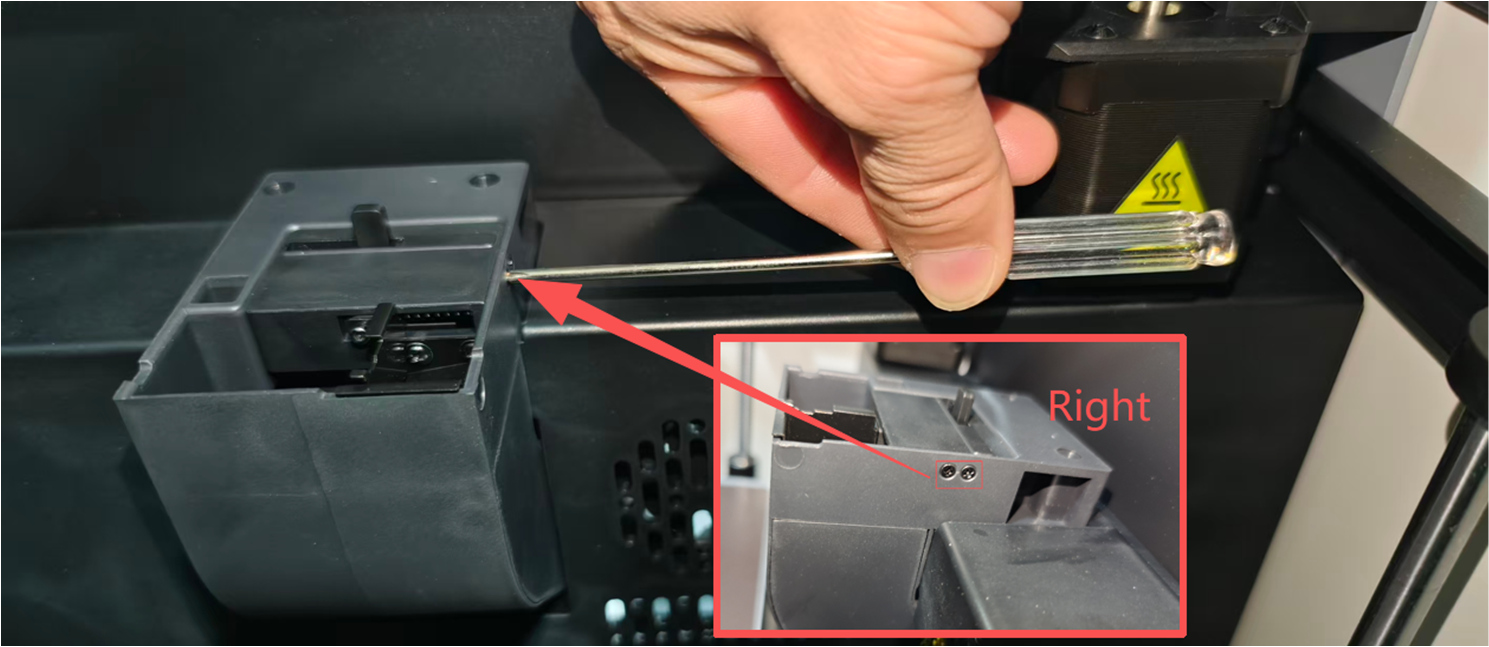

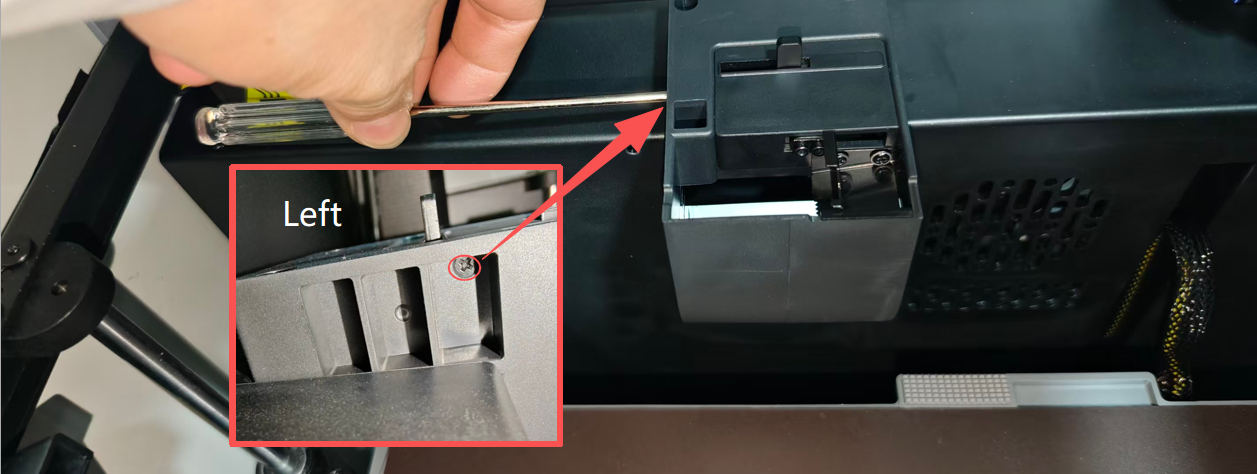

1. Use a PH0*2.0 Phillips screwdriver to remove the KA2*6 screws on both sides of the old magazine material assembly on the machine. (Note: one fixing screw on the left and two on the right.)

As shown in Figure: a and take out the magazine material assembly upwards.

As shown in Figure: b

|

|

|

|

|

Figure: a |

Figure: b |

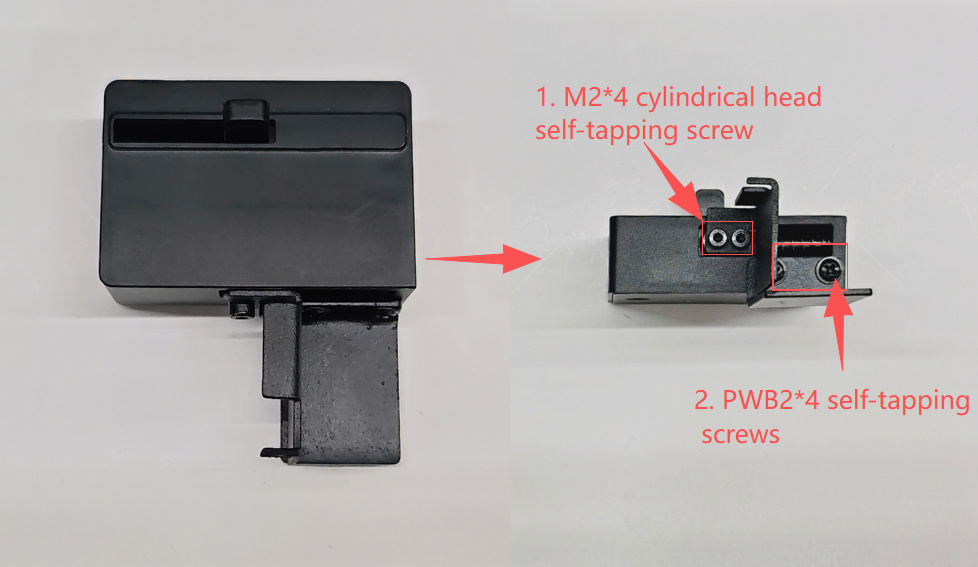

2. Use an H1.5 Allen wrench to remove the old pusher plate screws. Then use a PH0 PH0*3.0 Phillips screwdriver to remove the magazine material tray. As shown in the figure.

|

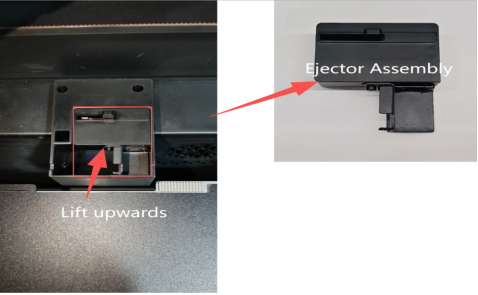

¶ Install the ejector component

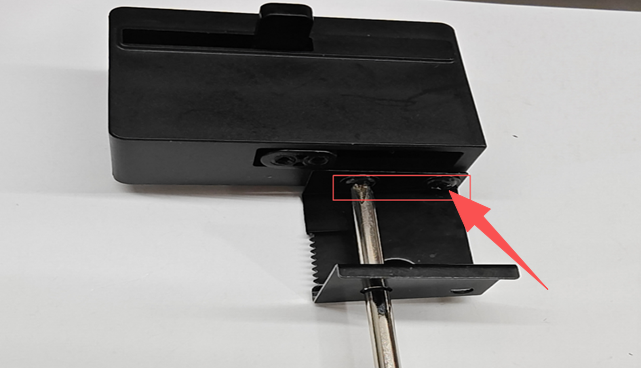

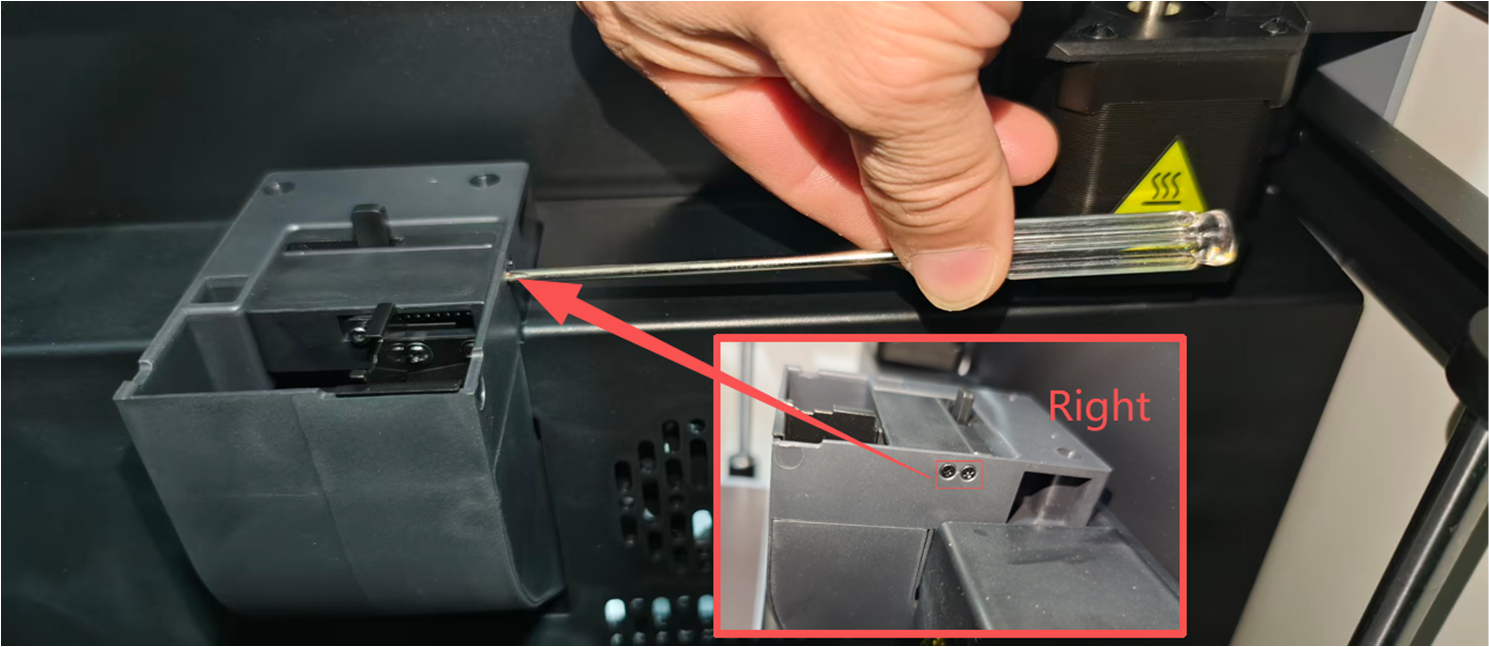

1. Fix the ejector tray to the ejector component and tighten the screws with a PH0*3.0 Phillips screwdriver. (Note: For the screw on the right, the screwdriver can lock the screw from the side as shown by the red arrow.) See the figure.

|

2. Fix the pusher plate to the ejector component and tighten the screws with a H1.5 Allen screwdriver. See the figure.

|

3. After replacing the above two parts, install the ejector component back into the machine's waste box. And tighten the screws on both the left and right sides.

|

|

Optimize the above operation steps. If you have any questions or need help, please send an email to us support@artillery3d.com for after-sales service.