¶ M1 Pro 3DReplacing the soft magnetic pad on the printer's heated bed

Prepare accessories, soft magnetic sheet for the heated bed surface.

Soft magnetic sheets are magnetised rubber laminates affixed to the aluminium substrate of the heated bed. Their primary purpose is to ensure a robust magnetic bond with the PEI build plate.

.jpg) |

—— When should the soft magnetic sheet be replaced? When it exhibits extensive damage/breakage, bulging, or loss of magnetic properties that compromise the secure adhesion of the PEI build plate.

Please note: Minor scratches, dents, or small-scale damage to the surface magnetic tiles will not affect printing functionality. Provided the build plate PEI remains securely fixed in place, replacement is not required.

List of tools used:

1. Gloves 2. Scraper 3. Cleaning cloth 4. Alcohol

¶ Remove the soft magnetic plate.

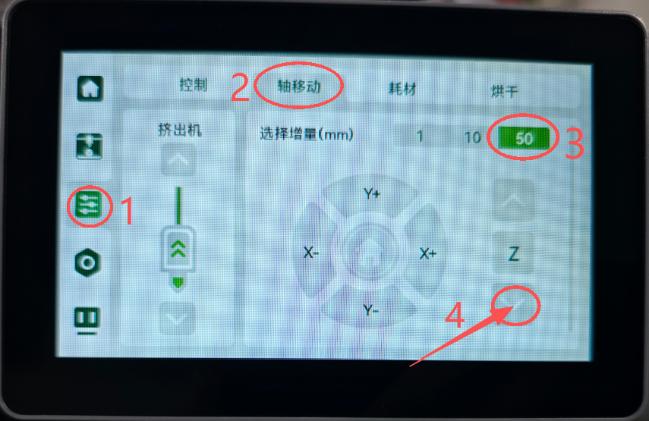

Step 1:Operate the Z-axis movement on the screen axis movement interface to lower the heated bed. As shown in the diagram:

|

|

|

Step 2: Tap the screen to activate the heated bed, raising its temperature to approximately 60°C. This facilitates softening the adhesive backing of the magnetic sheet for easier removal. Using a scraper, gently lift the magnetic sheet from the designated position, as shown in Figure a. Manually peel the magnetic sheet off in the opposite direction and thoroughly clean the surface of the heated bed's aluminium substrate. (Caution: When the heated bed is active, wear protective gloves during removal to prevent burns.) As shown in Figure b:

|

|

|

| Figure a | Figure b | |

¶ Fit the soft magnetic strip

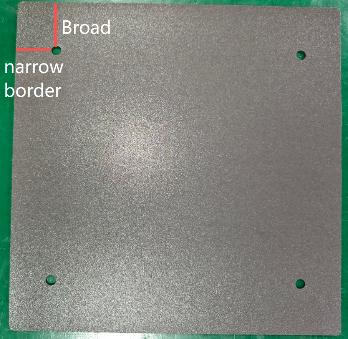

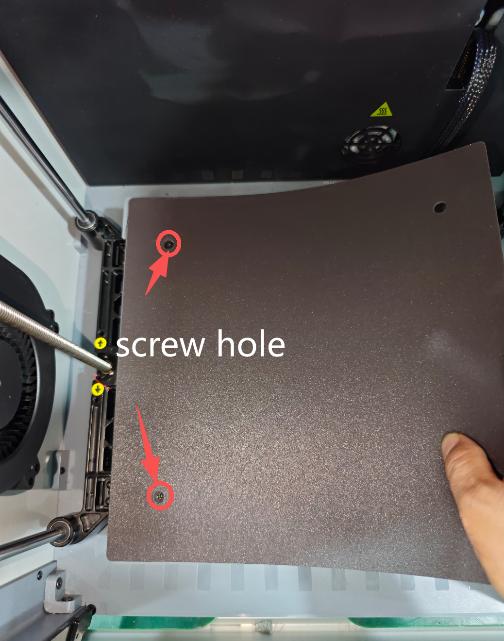

Step 1: Before installing the soft magnetic plate, note: The distance between the screw holes on the wide and narrow edges indicates the symmetrical placement position. As shown in the diagram:

|

|

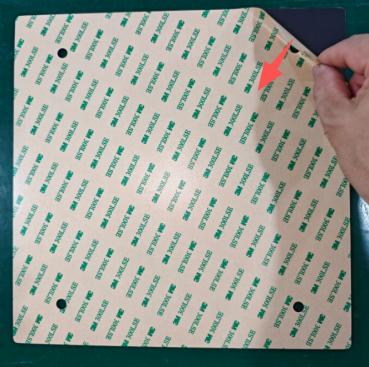

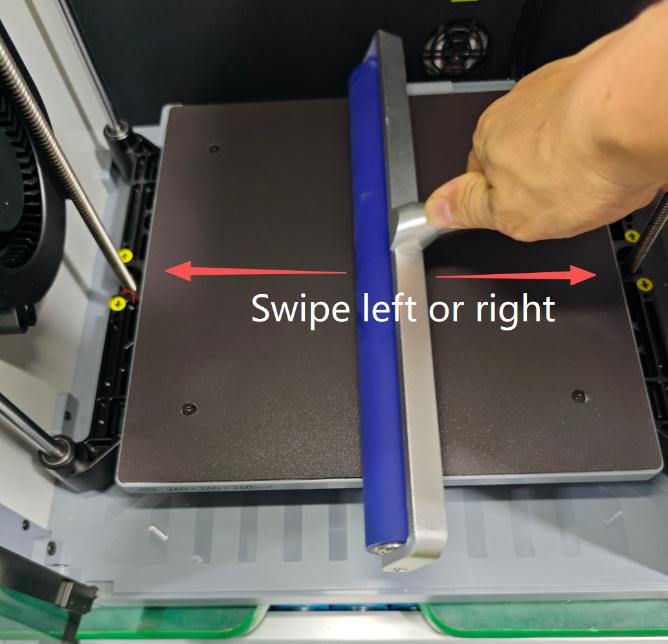

Step 2: After removing the backing paper from the soft magnetic sheet, align it symmetrically with the screw holes on the heated bed's aluminium substrate and press it flat as shown in Figure a. Once adhered, use a squeegee and the backing paper from the soft magnetic sheet to fold it into a suitable square shape (pressing back and forth to smooth it out) or use a roller, sliding it left and right to flatten the soft magnetic sheet, preventing any bubbling or lifting. As shown in Figure b:

|

|

.jpg) |

|

| Figure a | Figure b | ||

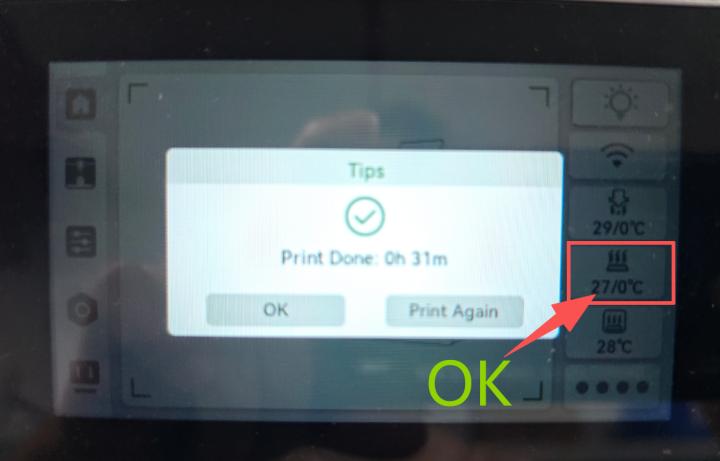

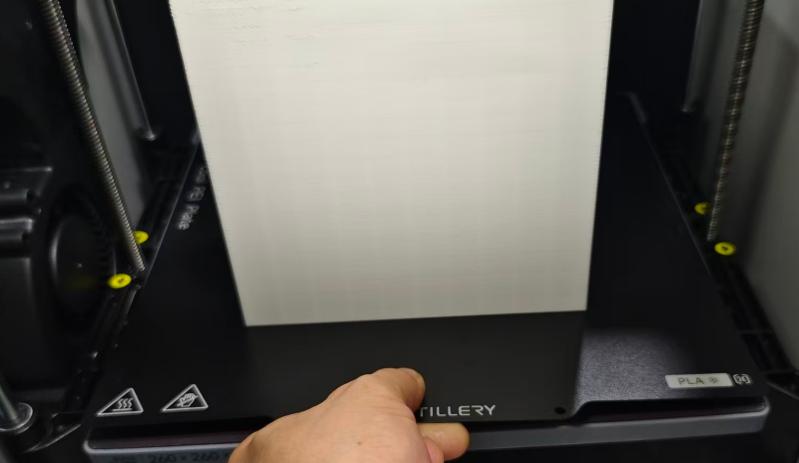

¶ Print correctly and remove the model

When printing models using high-temperature filaments such as PETG, ABS, ASA, PA, and PC, the heated bed reaches temperatures between 70°C and 120°C. Should the printer halt mid-print or complete printing, do not immediately remove the PEI sheet to detach the model. Please wait until the printer has stopped and the heated bed has cooled to below 50°C before removing the PEI sheet to detach the model.

|

|

Forcibly removing PEI from the heated bed at high temperatures may damage the soft magnetic sheet's adhesive backing, causing it to detach and leading to deformation of the bed's aluminium substrate. If the magnetic sheet peels up and is reapplied, bubbles or poor adhesion may occur. Even if successfully reattached, when the machine is restarted for printing and the bed temperature rises again, the edges may curl up or form a U-shape.

|

|

|